Custom Engineered Special

Steel Profile Shapes

We produce hundreds of custom special steel

shapes for a wide variety of markets and applications.

Our customers choose Precision Kidd cold drawn shapes because

they save time and money and offer superior quality.

We will be glad to do a free analysis of

your part(s). Click

Here (pdf)

Why

Cold Drawn Steel Special Profile Shapes Are Better Why

Cold Drawn Steel Special Profile Shapes Are Better

- Dramatically reduces machining time/steel

costs

- Significantly reduces material loss/improves yields

- Produces closer tolerances

- Improves manufacturing capabilities without adding machinery/tooling

- Reduces manpower/training

- Enables automated production of difficult parts

- Suits lean manufacturing techniques

- Lowest tooling costs for precision tolerances

- Enables smaller manufacturer to compete

- Enables larger manufacturer to re-focus manpower/resources

Note: Special Shapes/Profiles can be made in both bar and wire products and sizes.

| Sizes:

Special Steel Shapes: |

Bar:

from .028” to 3” thick and up to 5”

wide Maximum cross section 9 sq. in. |

Wire:

from .028 to .750” |

Cold Drawn Steel Shapes Can Save You Manpower, Capital and Labor Costs

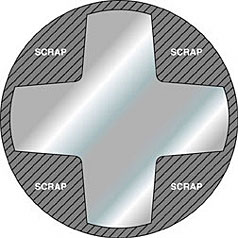

Cold drawn steel shapes/profiles could save you up to 75% or more on the cost of machining parts. You can eliminate machining steps and scrap loss. If you are machining "Premium Valued Material" (Tool Steel, High Speed, and Stainless Steels), the savings with special shapes/profiles can provide even more significant Yield Savings Dollars. Click the link below to see a video of how this is done.

Cold Finished Bar and Coil Drawing - YouTube

|